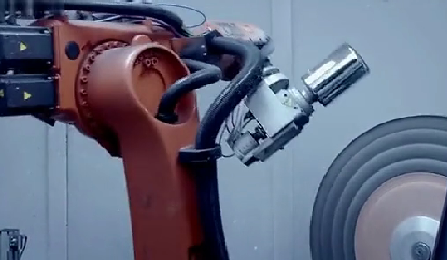

Industrial robot grinding, polishing, cutting and drilling

Industrial robots are redefining cutting, grinding and polishing processes with disruptive precision and consistency – far exceeding human limits in accuracy and boosting the yield rate to new heights.

Cutting and deburring – sharp as a blade, precise to the last detail

Precise dissection: 0.02mm-level repeat positioning accuracy, complex curve cutting in one go. Versatile material handling: from aluminum alloy plates to acrylic, from oak to food-grade resin, self-adaptive process parameters. Zero burr gene: intelligent collaboration of laser/water jet/vibration knife, cut surface as smooth as a mirror. Say goodbye to secondary processing, cost reduction by 30%*

Intelligent Polishing – Tactile Sensing, Craftsmanship Like EngravingCurved Surface Adaptation: 3D force control technology adjusts pressure in real time for seamless contour polishing without blind spots.

Consistency Revolution: Polishing the same workpiece thousands of times, the quality curve remains consistently straight.

Dust-Free Zone: Fully enclosed workstation + integrated dust removal system, safeguarding workers’ health.

Automobile wheels / medical devices / solid wood furniture – Surface roughness and precision freely controllable.

Polishing and Deburring – Micron-level Touch, Rebirth of Materials

Burr Hunter: Micro-sensing accurately identifies protrusions, leaving no place for complex inner cavities to hide.

Gloss Carver: Parametric adjustment of polishing trajectories, achieving a transition from matte to mirror finish.

7×24 Endurance: Continuous processing of titanium alloy parts, ceramic components, and other ultra-hard materials.

Aerospace blades / jewelry molds / precision gears – True craftsmanship lies in the details.

Why choose our robot system?

Intelligent process library: Pre-loaded with over 2,000 material processing parameters, switch production with just one click. Human-robot collaboration: Simple programming interface + collision protection, beginners can get started in 30 minutes. Cost black hole terminator: 4 times more efficient than manual labor, quick return on investment in 6 months.