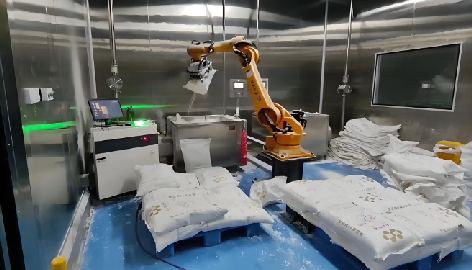

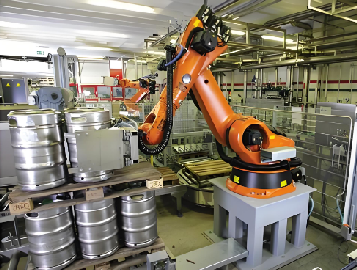

Industrial robot feeding materials

Intelligent Industrial Robot Feeding System – Fearless in High-Risk and Heavy-Duty Environments, Precisely Handling Various Forms of Materials

▶ Closed-Operation Cabin + Negative Pressure Dust Collection System: Isolating Contact with Dust and Volatile Substances

▶ Corrosion-Resistant Mechanical Arm Protective Cover + Explosion-Proof Design: Directly Facing Strong Acids and Alkalis

▶ Human-Machine Isolation Electronic Fence: Achieving “Zero Contact” throughout the Production Process

Intelligent Self-Adaptive Grasping

Multi-Spectrum Fixture Library:

– Vacuum Suction Cup Array: Non-Destructive Grasping of Flat Woven Bags and Cartons

– Hydraulic Gripping Arm: Firmly Holding Cylindrical and Rectangular Containers

– Electromagnetic Gripper: Precise Hoisting of Steel Buckets

3D Vision Recognition System: Real-time Determination of Material Forms, Automatic Switching of Grasping Modes within 0.2 Seconds

Benchmark in Heavy-Duty Performance: 300kg-Class Load Robots Stably Operating with an Error of mm

Inertial Compensation Algorithm: Eliminating Material Swinging, Preventing Spillage during Feeding

7×24 Hours Continuous Operation: Efficiency Increased by 400% Compared to Manual Labor

Typical Application Scenarios

☑ Chemical Plants: Feeding of Ton-Bags of Dyes and Hazardous Chemical Buckets

☑ Flour Mills: Fully Automated De-stacking and Feeding of 50kg Woven Bags

☑ Building Materials Workshops: Precise Pouring of Sand and Stone Buckets into Mixers

☑ Pharmaceutical Industry: Feeding of Raw Material Buckets in Sterile Environments